Rapid Prototyping

Rapid Prototyping 3D printing is a technology where a three dimensional object is created by laying down successive layers of material.

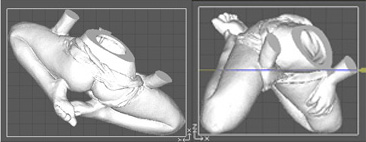

A three dimensional computer model is divided into thousands of cross-sectional slices. Those slices are then created by 3D printing machinery one layer at a time, by spreading a very thin layer of plaster based powder on a flat surface. A two dimensional inkjet print is made using binder in the shape of cross-section slice 1, then a new layer of thin powder is spread evenly across the top of the printed surface. The subsequent slice is then printed onto the new layer of powder and so on until all layers have been completed.

An example of what a single cross-section slice looks like can be seen in the image on your right.

This type of sculpture production is unparalleled by machining because there is no "tool" that has to reach inside undercuts. The material itself has similar properties to plaster allowing artists to further finish and detail the sculpture as necessary.

|